WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Apr 22, 2017· in this video, it is shown how ball mills work in running state. these ball mills are used where there is need of crushing hard material into powder.

Grinding aids for high performance cements ... The grindability of clinkers is usually compared on a lab scale by using a lab ball mill. By grinding ... or residual on sieve) than softer. Even though such lab tests hardly allow to forecast the energy requirement for cement production in industrial mills, a general indication of difficulties in ...

Ball Mill Manufacturers: - As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Master of Science in Engineering Johannesburg, October 2005

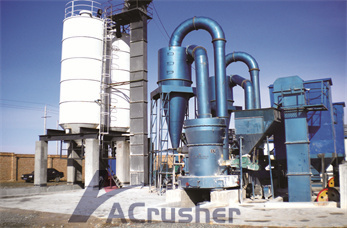

Sales Inquiry Photos Of Ball Mill In Cement Plants; FL ball mill for cement grinding. FL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Advanced Technology Best Cement Ball Mill For Mini Cement Plant, Find Complete Details about Advanced Technology Best Cement Ball Mill For Mini Cement Plant,Best Ball Mill For Cement Plant,Cement Ball Mill,Ball Mill from Cement Making Machinery Supplier or Manufacturer-Zhengzhou Hengxing Heavy Equipment Co., Ltd.

best photograph of ball mill in cement plant. photos of ball mill in cement plants, Cement clinker is usually ground using a ball mill the best way to get a,Ft long ball mill in a Cement Plant,Cement Factory Ball Mill This photo is . best ball mill manufacturers for cement plants samatourfr.

Cement Ball Mill Manufacturer Armeeschuettel. Cement ball mill for salegold ball mill manufacturerement ball mill for sale is professionally used to crush and grind the gold oreing it to process the gold ore can not only improves the use ratio of the gold ore get price raw mill in cement plantball mill manufactureraw mill in cement plant.

HeidelbergCement completed the capacity expansion project at its cement plant in Górazdze, Poland, with the commissioning of a new cement mill. The new mill, which is the largest ball mill in Europe, has a capacity of 1.4 million tonnes per year and ideally complements last year's increased kiln capacity.

We are making and supplying of Cement Ball Mill Plant in Zhengzhou, Henan, China. Cement raw material ball mill plant for grinding grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground.

The Major Equipment of Cement Production Line: The main equipment of cement production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln, rotary dryer and packing machine and so on.. Cement Manufacturing Process: The Handling Materials and Advantages of Cement Production Line:

view ball cement mill plant picture . Images Of Ball Mill In Cement Plant. photos of ball mill in cement plants. photos of ball mill in cement plants, From large primary jaws and gyratories to cones and VSIs for tertiary and quaternary » Learn More. magnetite plant wet ball mill photos.

Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill. Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing.

Earlier studies on industrial scale multi-chamber cement mills have shown that diap hragms in multi- chamber ball mills can be considered as a kind of classifier >> Get Price; Ball Mills. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300-350 – TPH) and before implementing the project, we would like to

Oct 09, 2016· Cement clinker is usually ground using a ball mill. article or two is perhaps not the best way to get a clear picture of a complex process like cement production. Ball Mill for Coal Grinding - Exporter from Meerut. ... Cement Plant Ball Mill Spare Parts - Mill Support Roller Cement Ball .

Cement Plants. Get Best Quote. Fertilizer Plants. Get Best Quote. VSK Portland Cement Plants. Get Best Quote. Rotary Kiln Plants. Get Best Quote. Plant Installation Turnkey Project. Get Best Quote. Reach Us. Praveen Kumar Sharma (Managing Director) G1-1428 Phase-5 & A-590A Phase-1, RIICO Industrial Area, Bhiwadi

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

Photos Of Ball Mill In Cement Plants: Mine Girnding Mills. zenith machine in Cement raw materials processing plant photos of ball mill in cement plants. zenith provide the ball mill for cement plant solution case for you. Get Price. Cement Ball Mill Photos: Mine Girnding Mills - designcamp .

Ball Mills. This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo Gallery Cement Plant Erectors, India

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture.

Rotary Kiln Cement Plant . The rotary kiln has an important role to play in the cement manufacturing process taking place in the cement plant. At Technomart, we specialize in manufacturing efficient and performance-oriented rotary cement kilns for successful completion of cement production.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

photos of ball mill in cement plants. photos of ball mill in cement plants - technobit . photos of ball mill in cement plants - makabsworg. ONE KILN - 13,000 tpd - - photos of ball mill in cement plants,21 May 2008, fident that the long-term global picture remains bright At, systems and cement ball .