WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Grinding mill process design. Choosing an appropriate grinding circuit configuration depends on your ore characteristics and mine plan. Outotec has extensive knowledge of comminution technologies and processes to ensure we provide the optimal solution for your needs.

Fine Grinding Mill American Pulverizer Company combines the economy and capability of hammermills to produce fine end products and provide a broad range of capacities and materials capabilities. American Fine Grinding Mills reflect over a century of experience in design, performance, and capacity for unmatched dependability, minimum maintenance ...

limestone grinding rate was not adequate and needed to be increased to maintain the original sparing. There are two main reasons that the original mill capacity effectively dropped by 50 percent or more. First, the original grinding circuit for each mill was designed to produce limestone slurry with a particle size such that 80

Application Range. With scientific & reasonable design and abovementioned unique advantages, HLMX ultra-fine vertical mills are applied widely in metallurgical, chemical, and non-metallic industry, for grinding of various materials, such as limestone, gypsum, coal, barite, calcite etc.

Limestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate production. It is the main raw material of glass & cement production, it also can be used in the areas of building materials and poultry feed.

Vertical roller mill design (1) Design of grinding disc speed and grinding roller size. Vertical grinding of high-fine limestone powder, first of all to ensure the fineness of limestone powder, under this premise, consider the grinding efficiency, mill output, stabilize the bed, and run smoothly. The grinding wheel speed and the size of the ...

Alibaba offers 1,930 limestone grinding ball mill products. About 96% of these are mine mill. A wide variety of limestone grinding ball mill options are available to .

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Jul 23, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Raw Mill Design For Limestone Grinding Image Results. More Raw Mill Design For Limestone Grinding images . Read more. Cement Kilns: Size Reduction and Grinding. Size Reduction and Grinding The Rosin Rammler Distribution (RRD) is applicable to materials that have .

At present, with the development of a limestone grinding mill grinding technology, we can get more and more pure Limestone powder, which can be used in the paper, rubber, paint, coating, medicine, cosmetic, fodder, sealing, bonding and polishing and has more extensive usages.

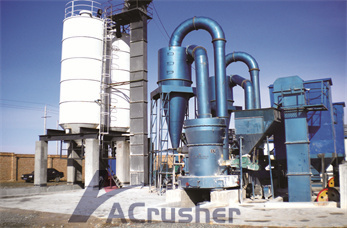

Customers want, and that is our goal, we produce ore crusher( limestone extraction and grinding), mill, crusher, mobile crushing plant, processing equipment, according to the specific needs of our design and production lines, fully the interests of customers.

Limestone Mill :. Limestone Mill is widely used for the grinding field of limestone.After being grinded by the limestone grinding mill (Raymond Mill), the limestone powder can be from 40 mesh to 325 mesh.The final powder size can be adjusted by the analyzer machine continuously.

Large mill (D>5.0 m (16.5 ft)) performance has been successfully predicted from small scale batch experiment for grinding kinetics and an RTD correlation for transport using population balance models.The effect of ball size must be properly taken into account in the scale-up. A design method that combined the kinetic scale-up findings and the transport of material through the mill has been ...

Polysius grinding mills can be of the overflow type or of grate dis-charge design. In 1976 Polysius adopted the design of shell-supported grinding mills using slide shoe bearings. Since this time, the design has been perfected based on the experience of more than 180 units operating all over the world in various industries. Today Polysius ...

Grinding Mill for Coarse Calcium Carbonate Powder Calcium carbonate grinding mill can grind limestone/calcium carbonate into different size or particle. The coarse powder grinding mill can make 1000-2000μm or 2360-5600μm and also 100 mesh or 200 mesh powder.

As a major Limestone Grinding Mill,Limestone Grinding Machine,Limestone Processing Plant manufacturer, Clirik can supply Raymond mill, Ball mill,Ultrafine mill,Hammer mill used for limestone grinding.

raw mill design for limestone grinding. raw mill design for limestone grinding spillerswharf. Mill (grinding) Wikipedia, the free encyclopedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many.

Limestone grinding mill,limestone powder production,limestone . Limestone grinding plant. Limestone grinding mill like . "High quality grinding mill of advanced design concept is the reason why our grinding mill is so popular in .

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The applications of ball mills are ubiquitous in mineral

fabrication of the ball mill, grinding test was conducted with the mill, using limestone as the feed material. This was followed by the particle size analysis of the ground product from the mill in order to determine the performance of the mill. The design results show that the minimum shaft

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains.. Millstones come in pairs. The base or bedstone is stationary. Above the bedstone is the turning runner stone which actually does the grinding. The runner stone spins above the stationary bedstone creating the "scissoring" or grinding action of the stones.

Alibaba offers 6,179 grinding mill for limestone products. About 86% of these are mine mill, 1% are limestone, and 1% are carbonate. A wide variety of grinding mill for limestone options are available to you, such as free samples.

Limestone Raymond Mill. Limestone is one of the common ore in nature. The grinding machine that can be selected for grinding is Raymond mill. Here is the analysis of the related information of the mill, such as its characteristics, basic performance and working principle.