WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

activated charcoal production micro grinding particle size. activated charcoal production micro grinding particle size effect of particle size on production efficiency copper milling gyratory crusher particle size Read more. optimum particle size for copper ore processing grinding mill equipment. Get Price; charcoal grinding coal

In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated. Silica ore was used as the test material.

May 08, 2012· In summary, we have looked at only three areas of feed mill efficiency: ingredient variation, particle size reduction and pelleting. We have seen that by gaining control we can improve efficiency, and savings in Cost of Goods Produced are realized.

In this method, oxides including mill scale are first ground to control particle size and then reduced by a gas, usually carbon monoxide, hydrogen or cracked natural gas at temperatures below the melting point of copper. Particle size and shape can be controlled within rather wide limits by varying the particle size and shape of the oxides, the ...

have an average particle size of 50-70 µm. Previous studies showed that the size of copper particles has a significant effect on the extent of the swelling of PM parts [2, 4]. This amplitude of the swelling seems to vary considerably with, among other things, the nature of the base powder, the type of formulation and the

Request PDF on ResearchGate | Effect of ball and feed particle size distribution on the milling efficiency of a ball mill: An attainable region approach | In this article, alternative forms of ...

Apr 01, 2019· Also, it is observed that the average particle size is smaller for Cu-10%ZrO 2 than Cu-5%ZrO 2 nanocomposites and both are smaller than Cu as shown in Fig. 2. However, the particle size reduction observed after 10 h of milling, the deviation of the particle size is still large.

EFFECT OF CORN PARTICLE SIZE MILLING ON BROILER, PULLET, AND LAYER GROWTH, PERFORMANCE, AND DIGESTIBILITY A Thesis in Animal Science by ... 1200, and 1500 µm by hammer mill. Energy and machine efficiency show larger PS (1200 and 1500 µm) lend themselves to greater efficiency, ...

manufacturers and users is to disperse all nanoparticles to their primary particle size. To this end, Netzsch Fine Particle Technologies has developed a variety of advances in fine bead mill equipment to carry out the tasks associated with grinding at the nano level – .

Mar 23, 2018· Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The machine consists of an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill .

effect of particle size on production efficiency copper ... effect of particle size on production efficiency copper milling 4.6 - 4358 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. Get Price

All cereal grains fed to swine need to be processed to reduce the particle size by cracking, grinding, rolling, extruding, expanding, or other method before being mixed with other ingredients and fed as a complete diet. Processing improves the utilization of grain nutrients primarily through improved digestibility. Cereal grains with hard seed coats (grain sorghum, barley, and triticale) have ...

Jan 31, 2018· The grading wheel has unique structure, good grading effect, good particle size, no big particle pollution and stable product quality. It is ideal equipment for dry metal production.

Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device .

effect of particle size on production efficiency copper ... Effect of ball and feed particle size distribution on the In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated.

activated charcoal production micro grinding particle size. . effect of particle size on production efficiency copper milling. gyratory crusher particle size. Activated carbon for purification of alcohol. Get Price And Support Online; The Effects of Diet Particle Size on Animal Performance .

Effect of ball and feed particle size distribution on the milling efficiency of a ball mill: An attainable region approach ... It was also observed from the experimental results that in order to increase the milling efficiency of a ball mill, towards optimum production of material in the desired size class, there is a need to correlate the ball ...

copper crushing plant with particle size pdf. copper crushing plant with particle size pdf -- China Mining Equipment, pdf blending spreading fertilizer physical properti the density of fertilizer particles will influence the spreading characteristics of a product a heavier particle willNext: stone crusher plant in padga

What is the effect of particle size on reaction rate. Effect of ionic strength on rate of reaction Why does particle size effect the rate of osmosis Osmosis is the movement of a solvent through a membrane. A membrane's pores or empty spaces . Get Price. EFFECTS OF AGGREGATE TYPE SIZE .

Particle Size Distribution Effects that Should - zenith. This valuable mineral particle size distribution is not characterised by the solids ..... passing copper achieved by ball milling a copper ore in the laboratory for. Get Price

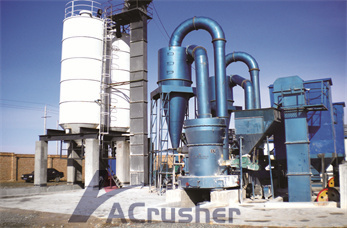

Effect Of Particle Size On Production Efficiency Copper Milling Our company is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 30 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the ...

Jul 31, 2018· More Details : we will provide a professional answer and quality of services. If this video does not meet ...

requirements, that have to be fulfilled by pigment dispersions, include a particle size less than 150nm, colloidal stability, the compatibility of various ink components, and purity. Ultrasonic milling and dispersing is a well-known and proven technology to achieve small particles with particle sizes in the range from 500µm down to approx. 10nm.

Apr 05, 2018· Optimize particle size & distribution to maximize packing density & extraction efficiency ; Here I talk about the effects of milling on the cannabinoid and terpene composition of the plant substrate. We cannot point at any effect. But the terpene concentration will decrease quickly with milled material. It is important to extract quickly after ...