WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Slag is the collection of compounds that are removed. In many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace refractory lining from excessive wear. In this case, the slag is termed synthetic.

This study investigated the influences of ultrafine slag slurry (UFSS) prepared by the wet ball mill on the properties of cement and concrete. The results obtained were summarized as follows: (i) Wet ball mill could improve the size distribution of slag particles effectively. The slag decreased the slump of .

Manufacturer of Ball Mills - Slag Grinding Ball Mill, Mild Steel Continuous Ball Mill, Batch Type Ball Mill and Continuous Ball Mill offered by Precious Mech-Tech, medabad, Gujarat.

Dec 10, 2016· In this work the milling behavior of a high-carbon ferrochrome slag is investigated. Milling experiments for a typical HCFeCr slag were conducted using a 0.303 by 0.282 m laboratory ball mill to establish liberation as a function of particle size and to determine the associated key breakage parameters like the breakage function (B ij) and ...

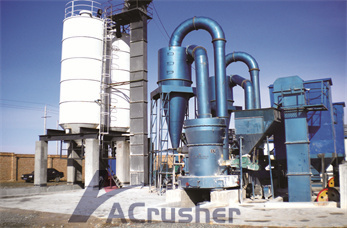

Slag ball mill is a kind of equipment used to grind the slag into powder particles The technical that uses the tube mill on the production of slag has been very mature The slag produced can be used as concrete admixture, reducing the project costs significantly and enhanced the compressive strength, tensile strength, shear strength and bending strength of the concrete Per machine power ...

In this work the milling behavior of a high-carbon ferrochrome slag is investigated. Milling experiments for a typical HCFeCr slag were conducted using a 0.303 by 0.282 m laboratory ball mill .

double jar ball mill. jul therefore, we have developed a small scale manual extraction .however, ball milling is required for all small scale methods in order to nbsp. Chat Online. crusher machine algeria - dpsjcampuscare . ... slag mill recycle plan - thedevondeli .uk.

Dec 10, 2016· In this work the milling behavior of a high-carbon ferrochrome slag is investigated. Milling experiments for a typical HCFeCr slag were conducted using a 0.303 by 0.282 m laboratory ball mill to establish liberation as a function of particle size and to determine the associated key breakage parameters like the breakage function ...

Ball Mill for Slag Crushing Slag Processing Plant Slag is an industrial solid waste which is mainly posed of the oxides of calcium iron silicon Get Price ball mill for crushing slag 187 slag crushing ball mill machinery supplier from india ball mill for slag crushing ball mill Read More.

Slag mill is mainly used for grinding steel slag,waste residue,mineral waste residue,gypsum,gravel.It also can be used for refractory material,fertilizer, ferrous and non-ferrous metal ore dressing, glass and ceramics production industry, etc. It's an important equipment in aerated concrete production. Slag mill is stable and reliable.

Features Slag ball mill is a kind of equipment used to grind the slag into powder particles. The technical that uses the tube mill on the production of slag has been very mature. The slag produced can be used as concrete admixture, reducing the project costs significantly and enhanced the compressive strength, tensile strength, shear strength and bending strength of the concrete.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as .

Nov 07, 2016· 100-3000t/d ball grinding mill for Cement, slag, coal, iron ore beneficiaiton. Tel:+86-18137823265 Email:sales@gwmcn Web:

The professional manufacturer and supplier of various grinding mills including wood chipping machine,raymond mill,wood powder machine,pulverizer,slag mill,ceramic ball mill,cement ball mill etc

ball milling of slag design; ball milling of slag design. Cement grinding Vertical roller mills versus ball mills - RuCEM . ... Compared to ball mill, zenith vertical mill has the advantages of small footprint, safe operation, high grinding efficiency and low energy consumption.

Sep 28, 2012· Production of slag cement with an MPS vertical roller mill at the cement plant ... For this granulated blast furnace slag... SBM crushers and vertical mills for mineral slag processing plant.

Slag Ball Mill -China Shanghai Shanghai Mining Machinery Co.,Ltd. Slag mill is the key equipment used for re-grinding the slag after it is pre-crushed. It is mainly applied in the superfine slag .

Ball mill for slag grinding is very important.It is also widely used in mining, construction industry and plays an important role in the economic development. Ball mill is low-cost, high efficiency, less pollution.These devices can help the majority of businesses complete the production plan efficiently and create a good production environment.

Slag ball mill is the key equipment used for re-grinding the slag after it is pre-crushed.It is mainly applied in the superfine slag powder production industry and .

Slag ball mill is made of high quality steel products, and very durable, and slag ball mill has a long service life, high production of slag and slag fineness of the characteristics of large, be applied to refractory material, fertilizer, ground construction, cement industry and chemical industry etc, suitable for all kinds of ores and other ...

Steel slag ball mill is an important equipment in the main machine hall.The capacity of ball mill directly determines the capacity of the concentrator. Generally speaking, grinding workshop works 24 x 365, but due to the equipment maintenance problems, there will be a day for maintenance per month, so work time becomes 330 days a year more or less.

This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample'. You can find the SG of each mineral samples on the other table.

Slag ball mill is made of high quality steel products and very durable and slag ball mill has a long service life high production of slag and slag fineness of the characteristics of large be applied to refractory material fertilizer ground construction cement industry and chemical industry etc suitable for all kinds of ores and other abrasive materials can also according to the nature of the ...

Page 1 Ball Milling Theory Introduction: Figure 1: Ball milling terminology. ... powder slowly burned with pools of bubbling white slag! It wasn't until 14 years later with the publication of Lloyd Sponenburg's dissertation on ball milling in American Fireworks News (December 1995) that I was finally able to make commercial quality meal powder. ...