WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Dec 13, 2011· This website will provide the most useful technical information about COAL BASED THERMAL POWER STATIONS particularly for power engineers those are working in thermal power plants-Designed by Er.VENKAT DJ. 13 December 2011. ... .Medium speed mills like bowl, ball and roller mills. C).High speed impact mill. ...

Jan 03, 2016· How A Coal Pulverizer Works - Coal Grinding Process | 3D Animation | Williams Patent Crusher - Duration: 4:59. Williams Patent Crusher and Pulverizer Co., Inc. 29,944 views

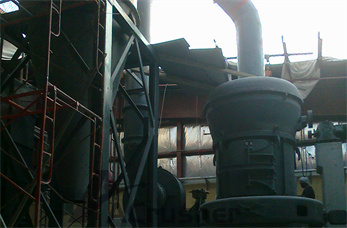

mill coal pulverizers in power plants . Coal Mill Vs Pulverizercoal Mill Working. ... Coal mill pulverizer in thermal power plants 1 COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY; 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form ...

coal pulverising bowl mill in thermal power plant. coal pulverising bowl mill in thermal power plant. Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel ...

Inner Cone In Thermal Plants . b h e l coal mill inner cone - redcrossanand. inner cone in bowl mill in thermal power plant. bhel coal mill inner cone, The Gulin coal mill inverted cone COAL MILL PULVERIZER in . price

Neha Engineering Works - Offering Power Plant, Boiler, Mill & Coal in Vadodara, Gujarat. Read about company and get contact details and address. | ID: 6403607262

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of fossil fuel power plants

The thermal power plant uses oil, coal or gas while nuclear plant uses nuclear fuel Nuclear Fuel energy is released by nuclear Fission Chain reaction in the core of a reactor 1 kg of Uranium U 235 can produce as much energy equal to 3086 ton of coal or 136 m 3 of fuel oil. 24/7 Online; Power plant maintenance: BOWL MILL WORKING PRINCIPLE

BHEL manufactures a complete range of Bowl Mill (Pulveriser) for all supercritical & non supercritical thermal power plant applications. Pulverisers are one of the major auxiliaries in a coal fired thermal power station . They are used for grinding the raw coal, so that the pulverised product at desired fineness can fed to and

THERMAL POWER PLANT : Proven source of High Chrome, Austenitic Manganese steel, Ni Hard, Carbon steel, Low alloy steel and High alloy steel casting. ... » Ball and Tube Mill Liners -Mn. Steel, Hi Chrome, Ni Hard ... » Ash clinker rolls » MOP Plate, Inner Cone, Ventury, Bowl Extension Ring » MPO, Valve Body, PF Bends » Upper Journal & Lower ...

Coal mill is an important auxiliary equipment for coal-powder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for bo...

Use Of Ball Mill In Thermal Power Plant. Ore ball mill in thermal power plant.Horizontaltubeball mill shri balaji a ball.Mill is a type of grinder used to grind and blend materials for use.In various types of industri a ball mill works on the thermal.Power plants these are get price get now. Read More

crushers used in power plants- crusher used in thermal power plant bathinda,crusher used in thermal power plant bathinda Crusher Used In 10mw Thermal Power Plant. Thermal power station Wikipedia A thermal power station is a Plants that use gas turbines to heat on YouTube and on YouTube video lectures by S. Banerjee on "Thermal Power Plants"

May 20, 2016· A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. There are five types of crushers; Jaw crusher, Gyratory crush...

(One) Reconditioned #412 C-E Raymond Bowl Mill rated at a base capacity of 8,000 Lbs/Hr. on 55 grindibility coal pulverized to 70% minus 200 mesh.Mill is capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove coal but at a lower rating.

maintenence of bowl mill in power plant. Appliions. Bowl Mills are used in: • Thermal power plants. • Cement Companies. • Steel Plants . Working regimes classifiion for predictive maintenance of mill fan . Abstract: In the present paper, the subject of analysis is a device from Maritsa East 2 thermal power plant a mill .

Liddell Power Station is a coal-powered thermal power station with four 500 megawatts (670,000 hp) GEC (UK) steam driven turbo alternators for a combined electrical capacity of 2,000 megawatts (2,700,000 hp). However, as at April 2018, its operating capacity has been assessed at .

Dec 12, 2016· Coal mill pulverizer in thermal power plants. 20121117 · Steam power plant by Nishkam Dhiman 672 views; coal pulveriser by pulverizer in mill plant for crushing coal High Speed Coal Pulverizer Crusher Price. Inquire now .Control for a power plant coal mill pulverizer having feedforward,Coal crusher alias, also known as .

Coal Fired Power Plant - YouTubeAug 11, 2015 Coal Fired Power Plant . How do you make electricity from coal, Effective Digital Presentations, produced this in ... HST hydraulic cone crusher. CS cone crusher. VSI6S vertical shaft impact crusher. Deep rotor vsi crusher. ... al mill operation in power plant by animation. Coal Fired Power Plant ...

Pulverizer Bowl Mill greenrevolution. coal pulverizer type xrp 1003 bowl mill MTM Crusher in coal mill pulverizer in thermal power plants Author Stream. 9 Nov 2012 Coal pulverizer/mill system One of the critical power plant components rpm High 900 to 1000 . Get Price

coal mill in power plant . Coal powder mill applied at coal fired power plant and thermal coal power plant and other plants. coal mill at power plant area, gold,copper,iron ore crushers coal mill at power plant area Limestone crushing industry Indai rock crusher plants made in germany belt conveyor used for sale feed size for sag mill.

Coal mill pulverizer in thermal power plants - SlideShare · 18.Inspection Following inspection parameters are critical for bowl mill performance: • Classifier internal condition • Deflector ring length • Inverted cone clearance • Journal assembly condition • Grinding roll-to-bowl clearance • Spring pressure for rolls • Pyrite scraper clearance • Pyrite rejects chute and/or ...

supply of Inner cone assembly with access door and inside ceramic lining suitable for XRP 803 mills: ... Supply of 36 Centre Distance Worm Gear and Shaft Assembly for HP 803 Bowl Mills ... E-Tender for the Supporting Roller Assembly for Drycon Conveyor in Bottom Ash Handling System - 150 Nos ...

Nov 23, 2013· TYPES OF MILL • Tube or ball mills: These are low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. • Vertical spindle mill: These are medium-speed machines that include bowl mills, ring roll mills, and ring and ball mills. The bowl mills are further divided into deep bowl or shallow bowl mills.